Sealing profiles

+43 5574 74177-0

GEBRA

Product selection

Select a product version so we can show you the exact availability and price.

Finishes

| Order number | Finish | ctn | UVP / Piece | Krt. | Total Piece | |||

|---|---|---|---|---|---|---|---|---|

| GEBRA-LINEAR | GEBRA automatic thermal cutting and welding machine with linear unit | 1 | 1 | EUR 0,00 |

|

| Order number | Finish | ctn | UVP / Set | Krt. | Total Set | |||

|---|---|---|---|---|---|---|---|---|

| GEBRA-PE-STA | Profile guide tool - standard profiles | 1 | 1 | EUR 0,00 |

|

|||

| GEBRA-PE-H/A | Profile guide tool - H/A standard pr. | 1 | 1 | EUR 0,00 |

|

|||

| GEBRA-PE-SON | Profile guide tool - Special profiles | 1 | 1 | EUR |

|

| Order number | Finish | ctn | UVP / Piece | Krt. | Total Piece | |||

|---|---|---|---|---|---|---|---|---|

| GEBRA-ABSAUGUNG | Suction | 1 | 1 | EUR 0,00 |

|

|||

| GEBRA-HALTERUNG | Bracket for suction unit | 1 | 1 | EUR 0,00 |

|

|||

| GEBRA-TISCH | Wooden table for GEBRA length stop | 1 | 1 | EUR 0,00 |

|

|||

| GEBRA-SPEZIALMESSER | Special knife, 18 mm high | 1 | 1 | EUR 187,71 |

|

|||

| GEBRA-SPEZIALMESSER | Special knife, 30 mm high | 1 | 1 | EUR 187,71 |

|

Description

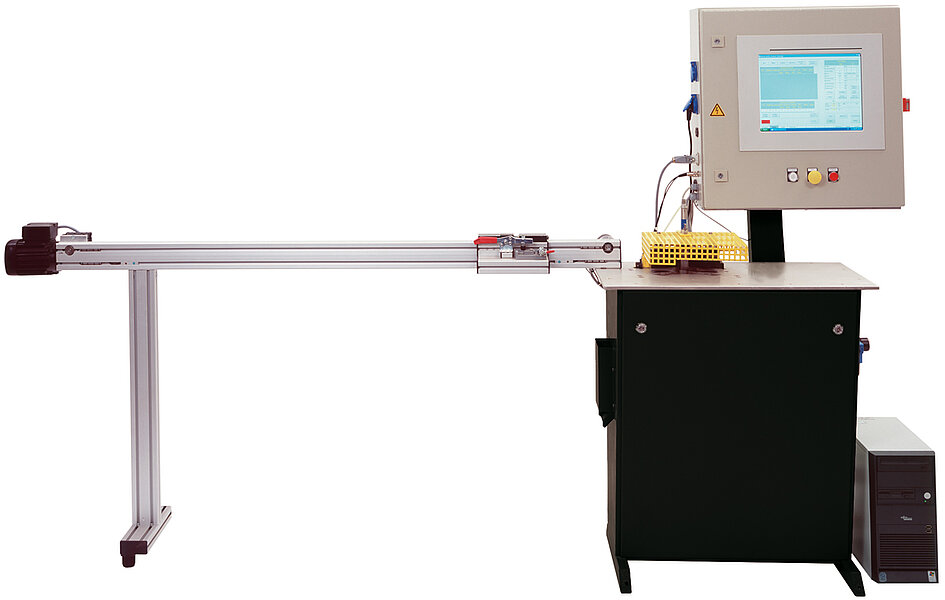

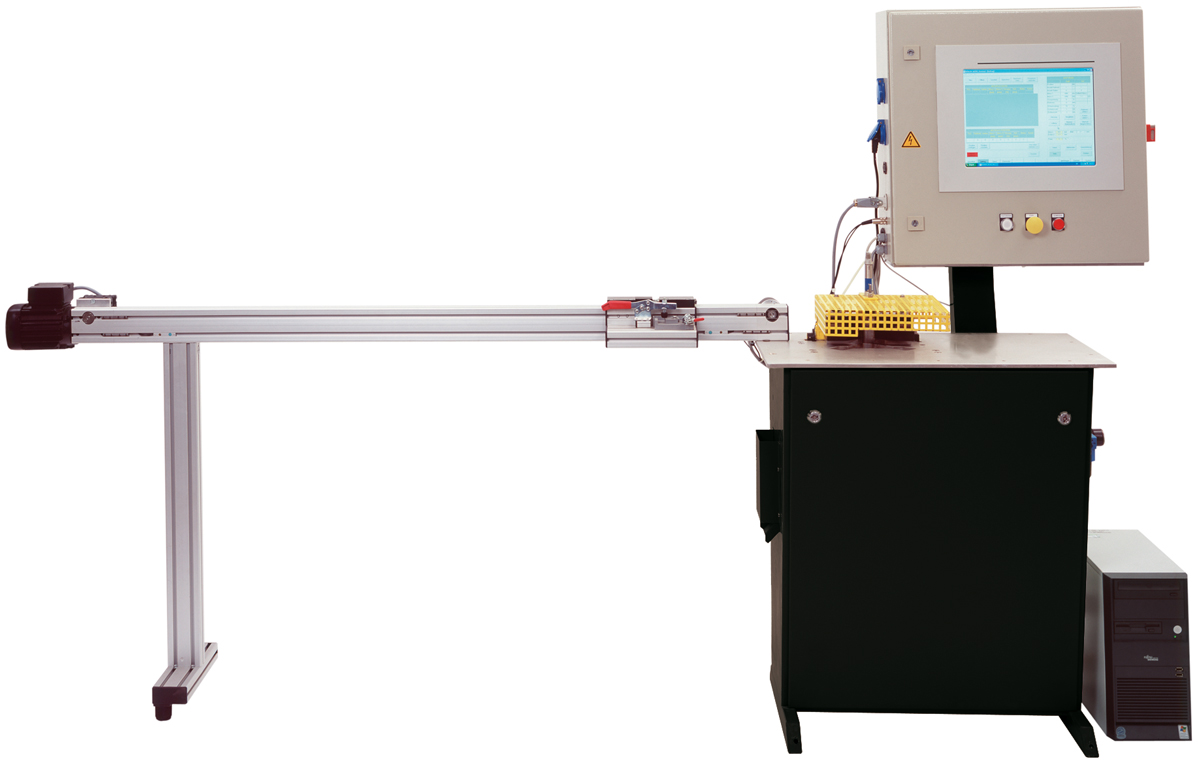

The GEBRA thermo welding machine with linear control is supplied ready for use with the following accessories: GEBRA automatic thermal cutting and welding machine with control unit for touchscreen operation, PC, mouse and keyboard. A linear unit for frame production up to approx. 3700 mm side length.

A profile guide tool is not included in the scope of delivery and must therefore be ordered separately.

Efficient sealing frame production: With the GEBRA automatic thermal cutting and welding machine, sealing frame corners can be cut and precisely welded together in a single operation. By controlling the welding temperature, welding time and closing time, the production process can be optimally adapted to different gasket profiles and material qualities and a consistent result can be achieved. The GEBRA thermo-cutting welding machine has been tried and tested many times. Our renowned window manufacturing customers have already produced many millions of sealing frame corners with the GEBRA thermo-cutting welding machine.

With the help of the GEBRA linear unit, sealing frames can be produced even more efficiently, as the worker can remain at the machine while the positioning unit moves the dimension slide into the desired position. This eliminates the adjustment times required for manual positioning of the sizing slides. The sealing frames are entered and processed via a touchscreen panel or the mouse/keyboard. All necessary data such as the number and dimensions of the sealing frames, any pretensioning, number of sides and corners, sealing profile number, order and commission number can of course also be processed. A connection to a higher-level host system for automatic data transfer is possible, but is not included in the price.

Technical equipment: electrical control, pressure regulator, pneumatic unit, 2 cutting blades, protective cover.

Technical data: 220 Volt, 190 Ampere, 50 Hertz, 15l/min. Air requirement, 100% duty cycle.

External dimensions: Height approx. 160 cm, width approx. 94 cm (without linear unit) or approx. 480 cm (with linear unit), depth 75 cm.