Sealing profiles

+43 5574 74177-0

A seal is a small component of great technical importance. That’s why Goll focuses on the highest material quality, excellent resilience for lasting tightness, and optimal shaping. We pay attention to temperature, coating, UV, and ozone resistance, and even offer a wide variety of colors. Everything needed for a perfect seal can be found at Goll — because we’re only satisfied when you are.

Window Seal AFK2054

Let the facts speak for themselves: suitable for sash rebate and overlap, thermoplastic elastomer (TPE) – recyclable, cord for stable corners, excellent resilience, optimal shaping, reinforced foot, hard back, optimal graphite gray color. Said it all? Not quite.

With our frame corner pieces, your double casement window will also remain perfectly sealed for the long term.

More info on the window seal AFK2054

Best to mitre the frame corners with our mitre pliers.

INFO ON MITRE PLIERS 90

Dry Glazing Seals.

Also important for professionals: every corner looks clean, even without a glazing specialist. The advantages of dry glazing are obvious — every window looks equally beautiful, and installation on-site is possible even at temperatures as low as +5°C.

Our unique selling point:

Triple glazing can have glass tolerances of up to +/- 1.2 mm. To ensure dry glazing really works, we supply silicone foam seals that compensate for these tolerances while also providing the necessary pressing force. That’s what it takes — and everything fits perfectly.

Fixed glazing with G-Fix® and T-Fix.

For fixed glazing, our dry glazing seals combined with the G-Fix® or T-Fix glass holders from Autera provide the perfect solution.

In the following video, you can learn about the advantages of G-Fix®. Or get more information directly on Autera’s website.

Middle Seals.

Goll supplies middle seals for various aluminum systems. The advantages?

The TPE thermoplastic elastomer and the weldability of the corners.

Thermoplastic elastomer is recyclable, can be supplied in any color, is easy to install in aluminum frames, and is especially flexible regarding pressing force.

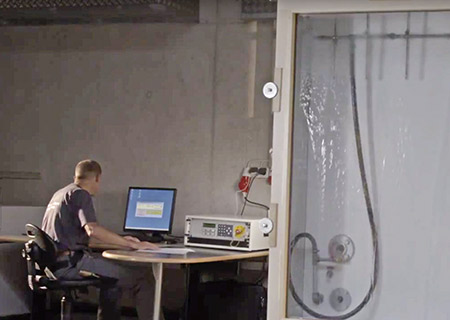

We produce the corners processed with the GOLL thermo-cutting and welding machine as a service within 8 to 10 days.

No major effort, no difficult vulcanization or bonding by other methods. Clean? With Goll.

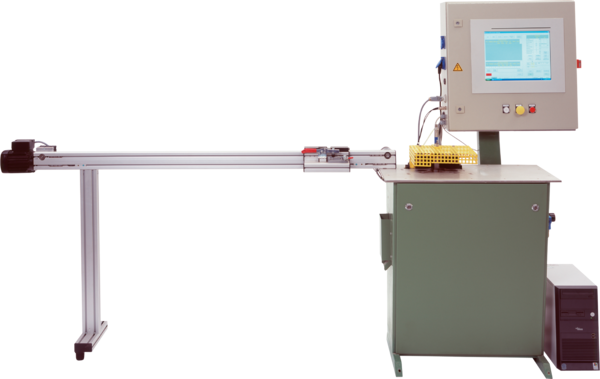

Sealing Frame Production.

The GEBRA thermo-cutting and welding machine with fully automatic length stop, touchscreen, and integration with production planning (AV) is one of the best machines on the market. Already, millions of corners are welded with it at over 100 customers. TO THE GEBRA THERMO-CUTTING AND WELDING MACHINE

Don’t do it yourself, have it done? No problem: have your sealing frames manufactured directly at Goll within 8 to 10 days. ORDER FORM